51 Temperature Ranges For Firing Glazes Coloring Pages

The ware will often not only go through a bisque firing but also a higher temperature glaze firing. 1186 - 1222C glazes that showcase a range of ceramic surfaces.

Pin On Color Steel Roof Wall Panel Roll Forming Machine

Ware must be fired at least once at a higher temperature first in order for the clay body to mature.

51 temperature ranges for firing glazes coloring pages. 1828 - 1945F 998-1063C. Of cone 46 opaque gloss glaze 525 pints of water. You should never fire a clay above its maximum Cone rating.

The optimal firing temperature ranged from 1190 C to 1250 C were selected through analyzing the relationship between the firing temperature and quality of glaze surface appearance. Buffstone has a high porosity at this temperature so glazes must fit well. Choose from our ten glaze series with firing temperatures between Cone 04 and 06.

While the pot is heating up you prepare your reduction chamber garbage can by adding the combustibles. 1 Glaze mixer states that most glazes are about 50 water so for every 1000g of powder you would add 1000mL of water 5. 1566F - 850C This range is usually used for luster glazes and very low-firing overglazes.

Reported on the microchemistry and microstructure of semi-industrially prepared double- DF and once-fired OF glazed tiles with ZrO 2 contents in the ranges of 697770 wt in DF glazes and 8511322 wt in OF glazes whereas ZnO was 190997 and 746-1310 wt in DF and OF glazes respectively. If it says Cone 6 you can fire it to any temperature UP TO Cone 6 but NOT over. Its Art in a Jar.

Gare Ceramics designs and manufactures ceramic bisque glazes fired color pottery glazes and acrylic paints for the Paint Your Own Pottery and DIY markets. Of cone 46 clear gloss glaze 525 pints of water. Of cone 46 Reactive Hi-Fire glaze 5 pints of water.

888 289-4273 My Account. End of porcelain range. As for glazes firing too high can result in runoff firing too low will make your pieces dry and rough and a glazes color can be affected negatively by any temperature variance as well.

Specialty Glazes Glazes for special effects and firing techniques. End of stoneware range. At this temperature the pot has sintered which means it has been transformed to the point that it is less fragile while remaining porous enough to accept the application of glazes.

After the desired temperature has been reached the kiln is turned off. Choose from our ten glaze series with firing temperatures between Cone 04 and 06. Therefore the safest clay to have in your studio is Cone 10 clay because you will never risk over-firing it.

Mullite and cristobalite two types of silica form as clay begins to convert to glass. Soaking holding the end temperature increases the amount of. 0 votes average.

However it crazed on buffstone after boiling water ice water test use 2931G instead. L212 crazes at cone 04. End of earthenware red clay range.

000 out of 5 You need to be a registered member to rate this. Try a Raku firing or add surface depth to another AMACO glaze. Be sure to consult the labels on your glazes for cone requirements and consider the type of clay youre using before choosing a firing temperature.

Out of the kiln all fit. The others are good. G2931F on F100 Buffstone L212 and L215.

Suitable for brightly colored pottery earthenware sculpture and school projects. This is unlike glaze which must be fired to the exact specified temperature range If clay over-fires it will first slump and bloat and then will melt and potentially cause a lot of damage to your kiln. Western raku is typically made from a stoneware clay body bisque fired at 900 C 1650 F and glost or glaze fired the final firing between 8001000 C 14701830 F which falls into the cone 06 firing temperature range.

According to the XRD and SEM results with increasing the firing temperature the content of whitlockite decreased which weakened the coloring of Fe 2 O 3 and formed glaze patterns. As the crystals bloom they produce dramatic colorful effects. The firing range is anywhere from about 1400 degrees to 1832 degrees F Sometimes Raku artists dont use glaze and then a pyrometer is used to determine when to pull the pieces from the kiln.

Particles start melting together to form crystals and materials shrink as they become more dense. For mid-range fire artists the crystal glazes maintain their color with increased crystal movement at the higher temperature. The bisque firing continues until the kiln reaches about 1730 degrees Fahrenheit.

1828 - 1945F 998-1063C High Fire Glazes AMACO has a variety of Cone 56 2160F - 2230F. Specific temperatures for bisque and glaze firing will be discussed below. Maycos Jungle Gems are gloss glaze bases with pieces of glass frit that melt during the firing process.

Low Fire glazes offer a wide range of colors and effects with a lower firing temperature. El-Defrawi et al. Firing temperature is important for Zero3 glaze.

To cone 013 approx. The process is known for its unpredictability particularly when reduction is forced and pieces may crack or even explode due to thermal shock.

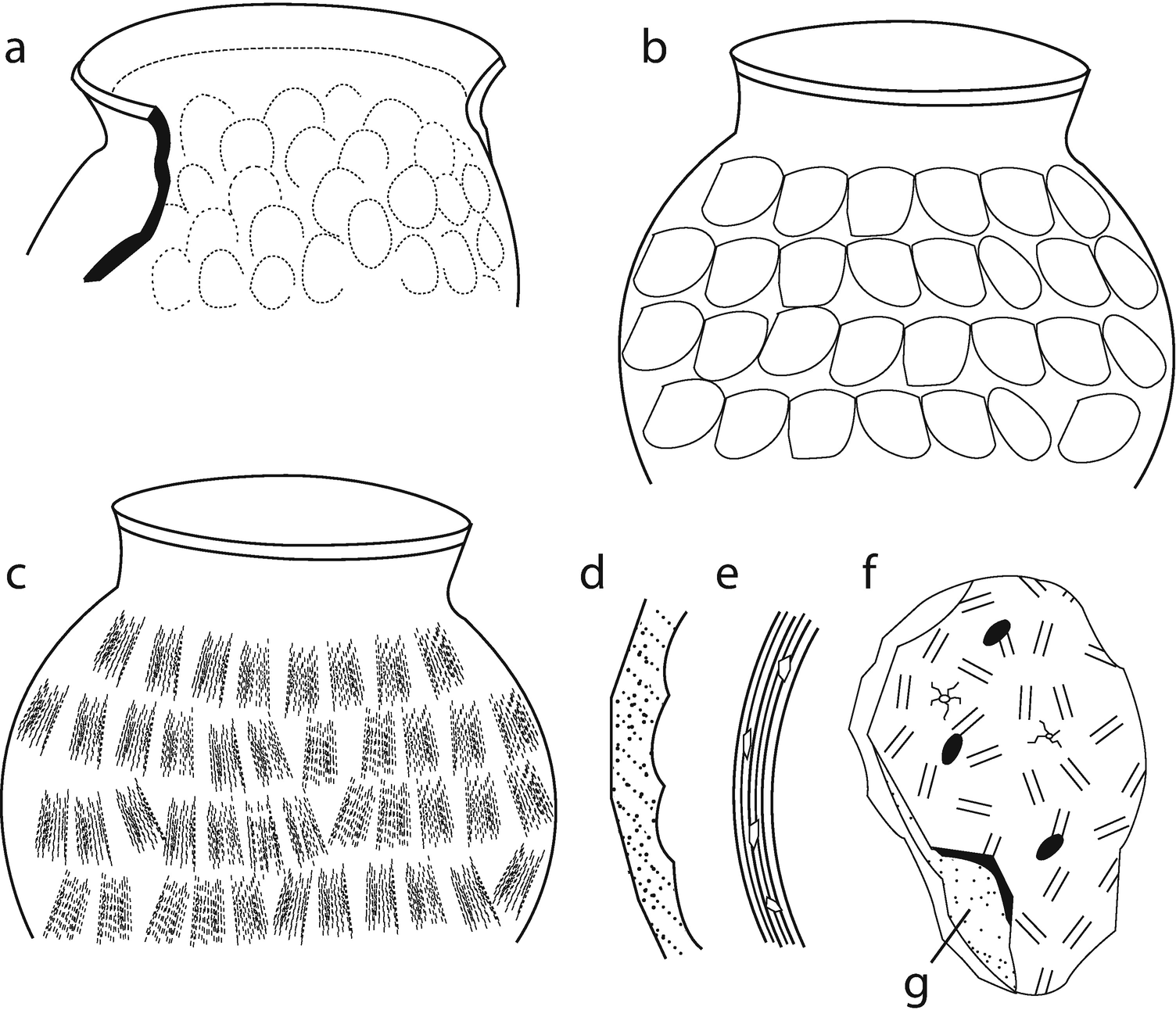

Ceramic Artifacts Springerlink

Pin By Ligia Maria Kerr On Slips Ceramic Glaze Recipes Glazes For Pottery Ceramic Texture

Pdf Glass Ceramic Glazes For Ceramic Tiles A Review

Thermal Conductivity Coefficient Of Sand Loamy Sand And Clay For Download Table

Abbesses Cermanic Set Red 04 460 460 Ceramic Dinnerware Set Ceramic Set Ceramics

Jun Ware Glazes Chemistry Nanostructure And Optical Properties Sciencedirect

Ceramic Artifacts Springerlink

Shop Modern Boho Home Goods Leif Ceramic Planters Planters Ceramics

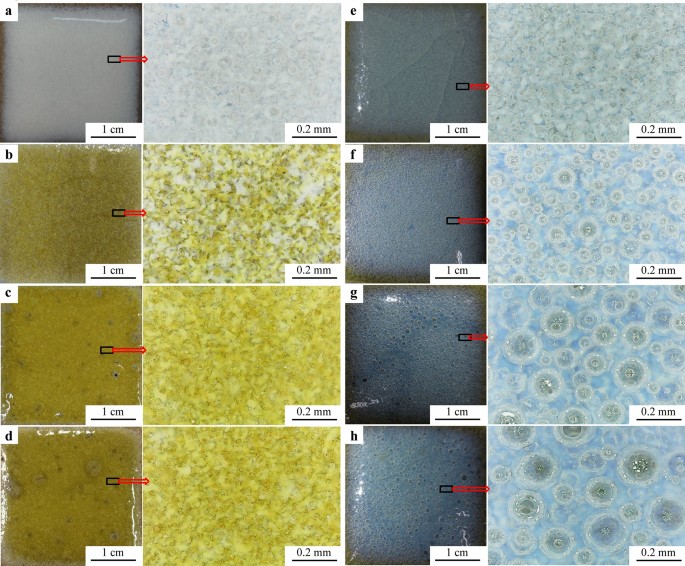

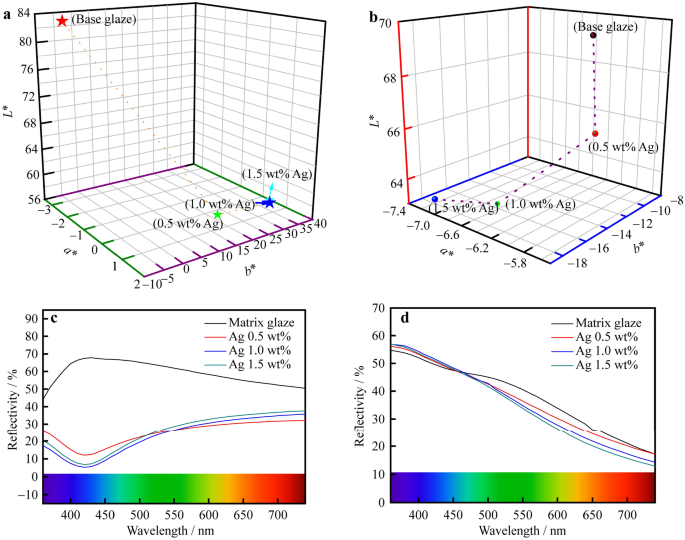

Nano Silver Induced Ceramic Coloring Via Control Of Glaze Interface And Phase Separation Springerlink

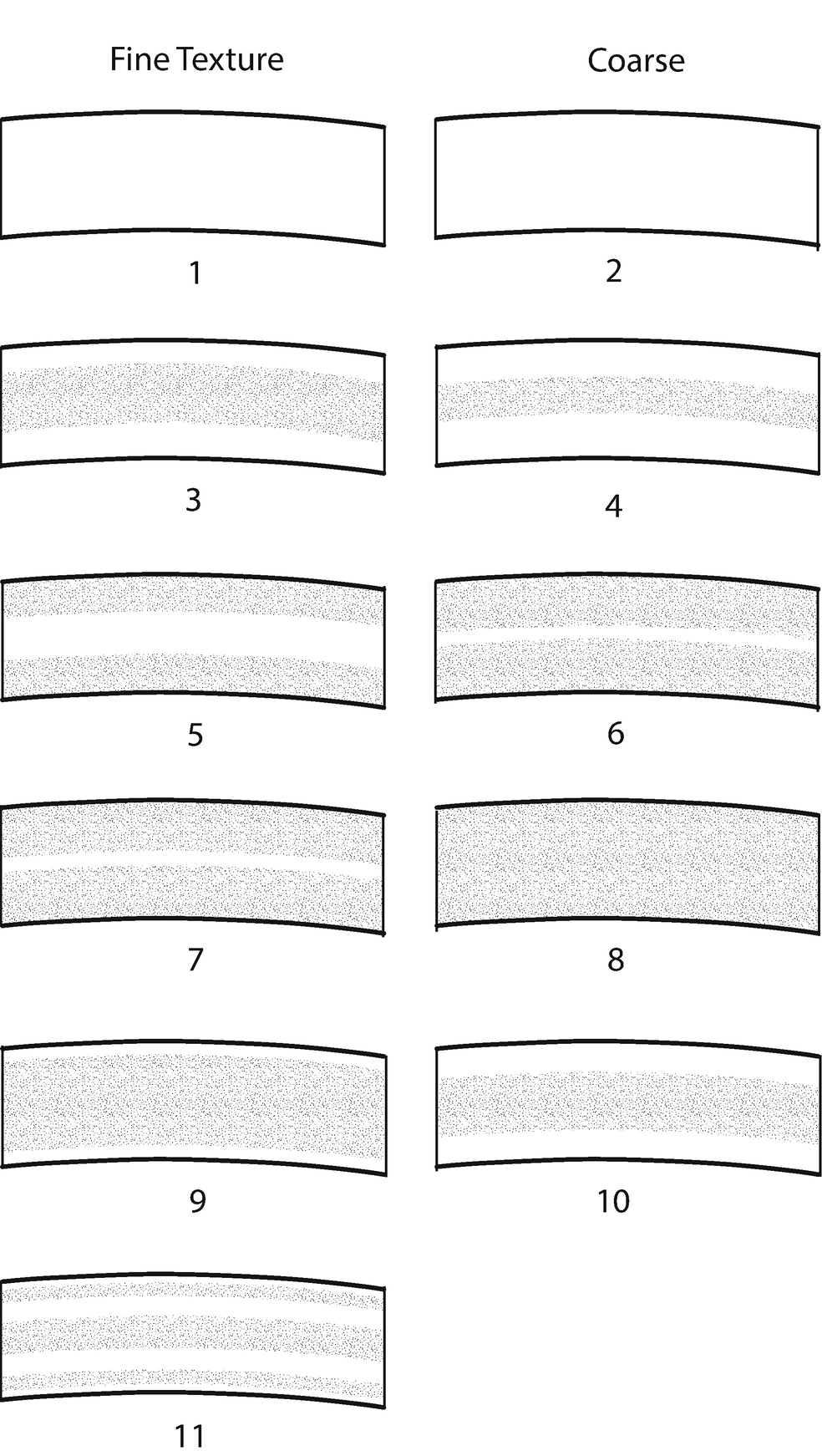

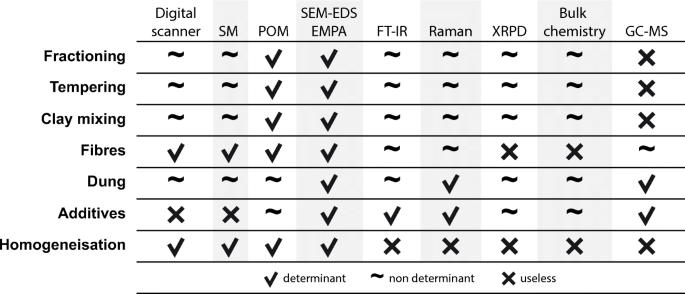

Ceramic Technology How To Recognize Clay Processing Springerlink

Clay Source And Firing Temperatures Of Roman Ceramics A Case Study From Plovdiv Bulgaria Lesigyarski 2020 Geoarchaeology Wiley Online Library

![]()

The Most Comprehensive Article About Rotary Kiln On The World Wide Web Internet Infinity For Cement Equipment

Pdf Glass Ceramic Glazes For Ceramic Tiles A Review

Nano Silver Induced Ceramic Coloring Via Control Of Glaze Interface And Phase Separation Springerlink

Pdf The Production And Distribution Of Pottery At Pompeii A Review Of The Evidence Part 2 The Material Basis For Production And Distribution

At Georgies How To Projects Technique Sheets

The Triaxial System Clay Quartz Feldspar Showing The Raw Materials Download Scientific Diagram